Pilbara Circular Plastics: Revolutionising HDPE Recycling in Mining

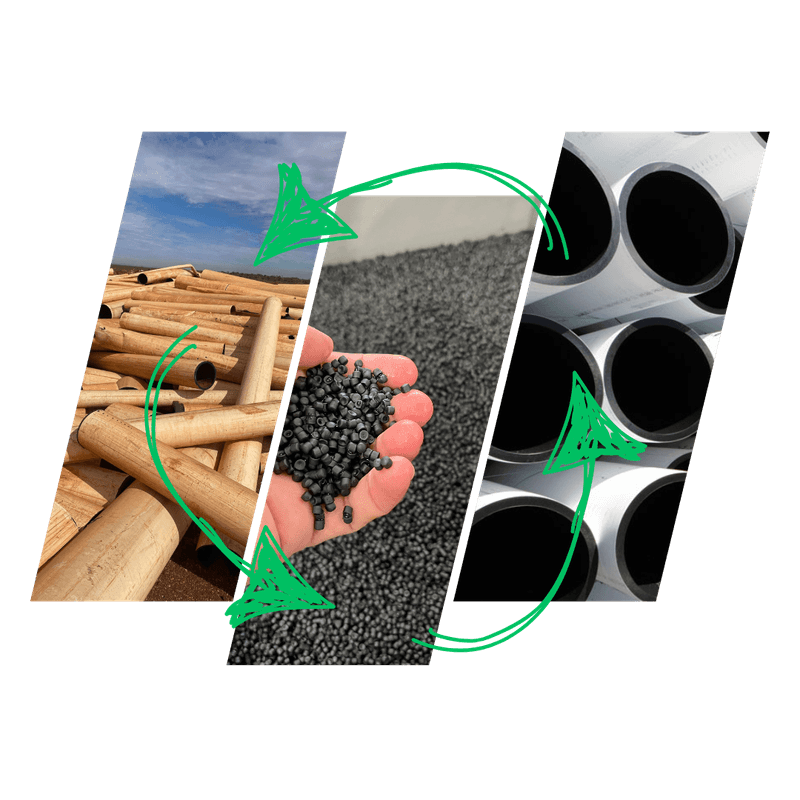

Pilbara Circular Plastics is transforming HDPE recycling in the mining industry by repurposing discarded mine dewatering pipes into high-quality, engineered pressure pipes. By integrating renewable energy and reducing emissions from plastic production, the initiative drives a circular economy in the Pilbara while lowering costs, reducing waste, and supporting regional sustainability.

The project addresses the mining sector’s reliance on virgin HDPE resin by delivering a carbon-neutral, cost-effective, and environmentally responsible alternative. Leveraging solar power to operate recycling and remanufacturing processes, and utilising an electric and hydrogen-powered fleet, Pilbara Circular Plastics ensures sustainability is embedded at every stage. Its location within the Pilbara iron ore region enables efficient logistics and seamless integration into existing supply chains.

Key Benefits:

Waste Reduction: Repurposes discarded materials that would otherwise end up in landfill.

Lower Emissions: Reduces production and transport-related carbon outputs.

Regional Impact: Creates jobs, strengthens local industry capabilities, and supports Indigenous engagement.

Cost Efficiency: Provides high-quality recycled HDPE at competitive pricing.

Operational advancements include a 71% increase in monthly throughput and expansion from two to 71 suppliers, ensuring a reliable and scalable supply chain.

By offering a circular economy model that combines environmental responsibility with economic viability, Pilbara Circular Plastics is redefining sustainability in the mining sector. Its innovative approach provides mining companies with practical solutions to reduce their carbon footprint while promoting regional growth, positioning the initiative as a leader in sustainable mining practices.